What are the delivery costs?

We offer Free UK Mainland Delivery on all orders over £20. Products shipped to outlying UK regions are excluded from free shipping.

Standard delivery is normally 2 - 5 working days.

Please view our delivery page for full information on UK and international delivery costs.

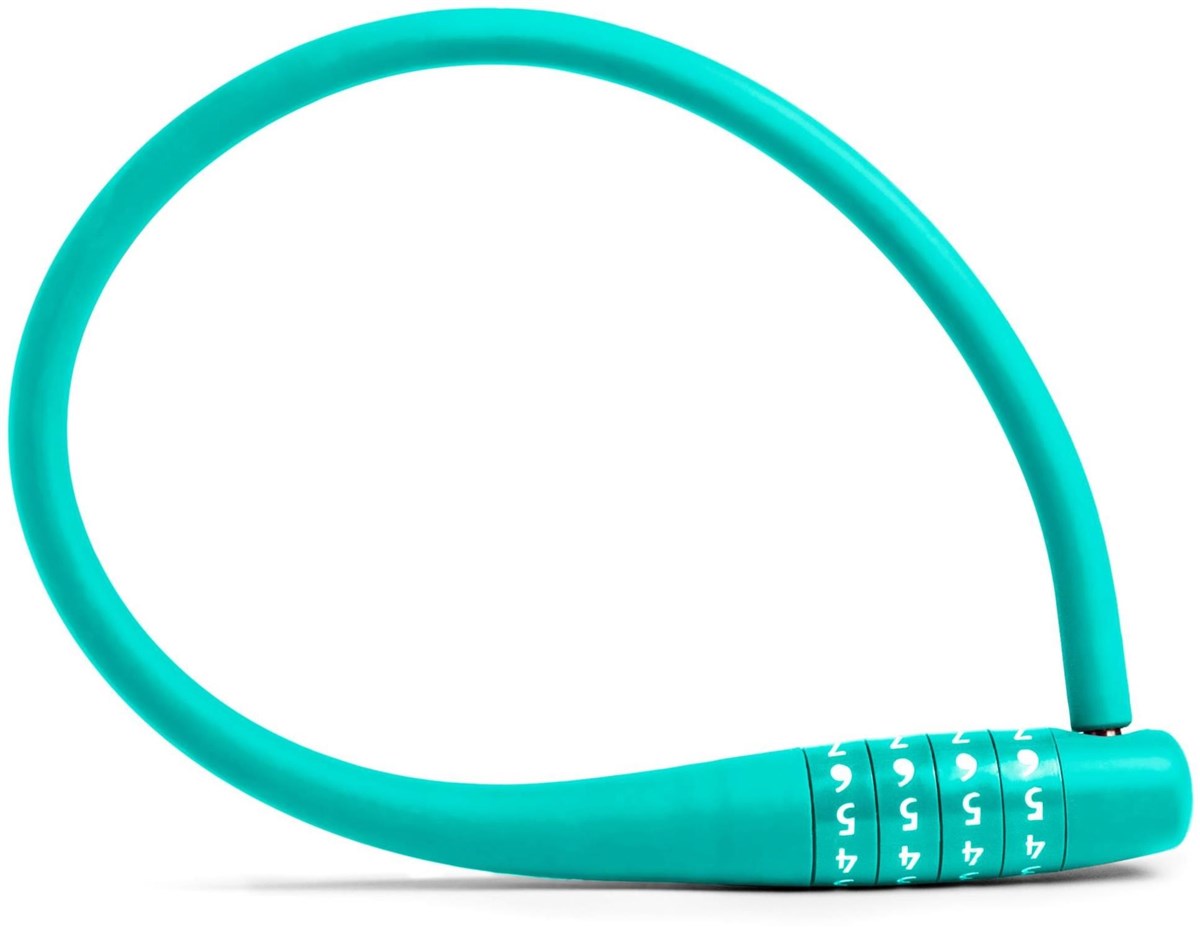

The Party Combo Lock is a seamless 620mm long cable lock. The lock comprises a braided high tensile steel wire cable and 4-number combination dial mechanism. Fibre-core technology combined with braided loose bound fibre core steel cable offers superior resilience against bolt-cutter attacks. A unique combination dial mechanism ensures a high-level of security with the ability to easily change the 4-number sequence as often as the user chooses. The entire cable and lock assembly is over-moulded using industrial grade UV-stabilised silicone. The Party Combo will not mark or scratch your bike and give you many years of service without degradation.

Specification

- Length: 62cm

- Weight: 300g

- Materials: Silicone overmoulded braided steel cable with fibre core

- Lock Type: combination

Features

- Security Rating: 30/100

- Body: Patented seamless over-mould using industrial grade UV stable silicone. Will not mark or scratch your ride.

- Lock Housing: 8mm Stainless steel locking shackle.

- Lock Barrel: Rotating dial lock barrel, with 10,000 unique combinations. Materials: Zinc Alloy Die Cast.

- Lock Cable: Braided loose bound steel cable with fibre core (making cable more secure in the event of bolt cutter attack).

- Outer Cable Diameter: 12mm. Internal Steel Cable Diameter: 5mm.

- Cutting Resistance: The TECHNOLOGY used on the FIBRE-CORE CABLES makes the Knog sausage locks five times stronger than the competition. Offering superior resilience and flexibility compared with locks using standard braided steel cable cores. The unique combination of materials crush before cutting, making bolt cutter attacks more frustrating for smash-and-grab thieves.

- Testing: We subject our locks range to a vast array of environmental tests to ensure they are fit for purpose for everyday use. These procedures are undertaken during research and development through to prototype and manufacture. These include: Drop Tests, Impact Tests, Corrosion Testing, Vibration Testing, Extreme Temperature Testing, Cycle Testing.

Occasionally, without notice, manufacturers change product design and/or specifications.

Knog Party Combo Combination Cable Lock

DESCRIPTION

DELIVERY

SIMILAR PRODUCTS

SEE ALL

OTHER CUSTOMERS BOUGHT

SEE ALL